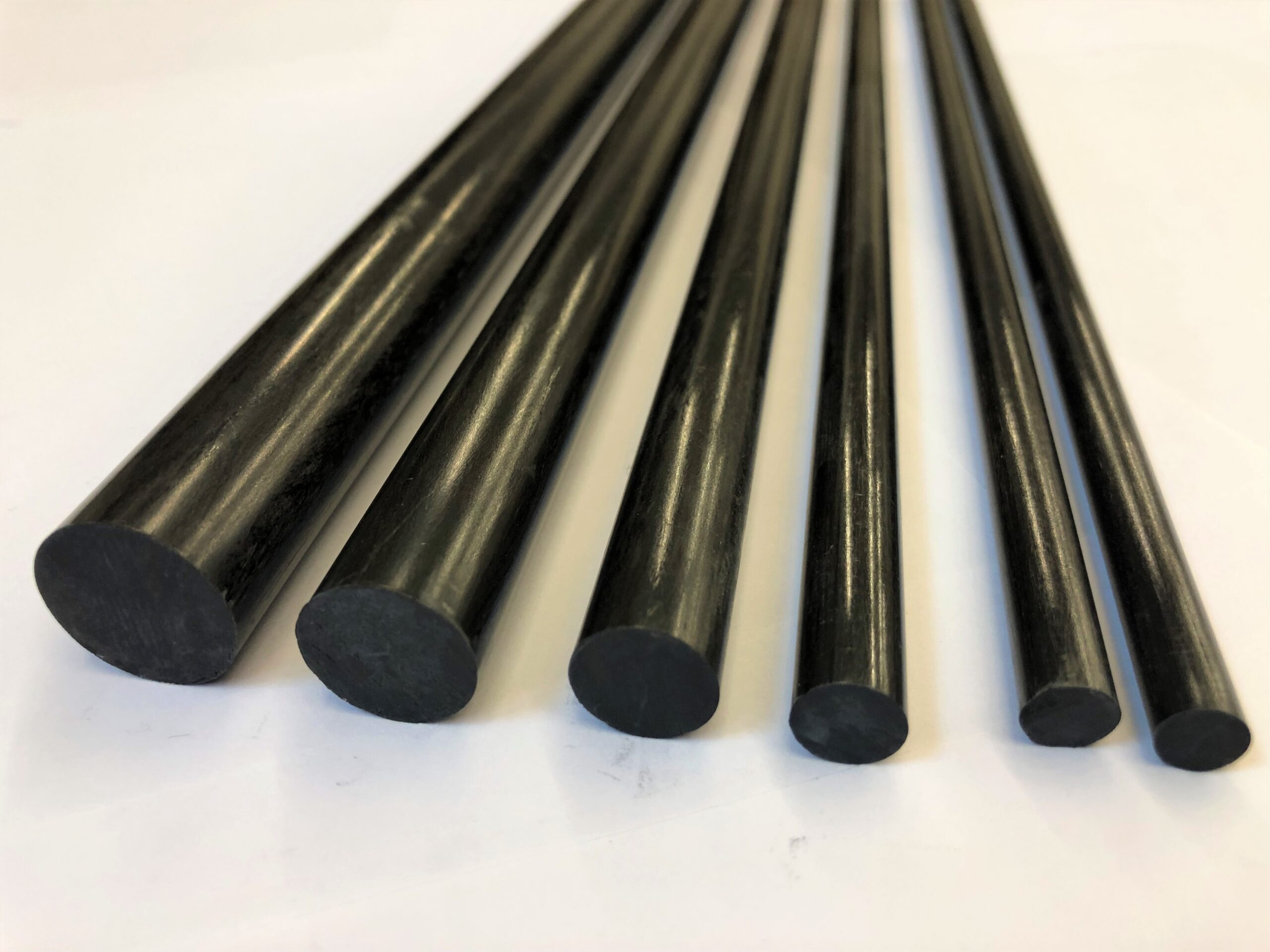

Solid carbon rods are especially stiff and lightweight. They consist of unidirectionally-oriented carbon fibers run through a resin bath and heated dies to make them extremely strong longitudinally – our customers often use them to replace metal in harsh environments or situations in which weight and strength are important factors.

Using a proprietary pultrusion process, our Micro Pultruded Solid Carbon Rods are available in a .020” – 0.156” diameter range and feature a high FvF (Fiber volume fraction) of 67-70%. This makes them stiffer than comparably-sized solid carbon rods. Additionally, the matte exterior makes for a ready-to-bond surface. No sanding needed, just clean and you’re ready to apply adhesives.

Larger-diameter Pultruded Carbon Rods have a FvF of 60% and have a glossy finish – you might need to sand the surface before bonding.

Goodwinds Composites sells solid carbon rods as small as .020” in diameter and as large as .750” in diameter. All lengths listed are +/- 0.062″ and all diameters listed are within +/- 0.005″. We are happy to custom cut your carbon rod to a specific length. Please contact us at [email protected] or 206-632-6151 for large orders and custom cutting or machining.

Click on the product number to view product details, product pictures, related products, and more!

Micro Pultruded Solid Carbon

Pultruded Solid Carbon

Carbon Rods less than .156"

| Minimum Properties | Standard Modulus |

|---|---|

| Tensile Strength | 320 ksi / 2.34 GPa |

| Tensile Modulus | 19.5 msi / 134 GPa |

| Compressive Strength | 270 ksi / 1.90 GPa |

| Compressive Modulus | 19.0 msi / 131 GPa |

| Fiber Volume | 67% |

| Ultimate Tensile Strain | 1.30% |

| Diameter Tolerance | +/-5% |

| Glass Transition Temperature | 100° C |

| Matrix Material | Bis F Epoxy |

Carbon Rods greater than .156"

| Minimum Properties | |

|---|---|

| Tensile Strength | 250 ksi / 1.72 GPa |

| Tensile Modulus | 20.0 msi / 138 GPa |

| Ultimate Shear Strength | 6.0 ksi / 41.3 Mpa |

| Ultimate Tensile Strain | 1.50% |

| Flexural Strength | 265 ksi / 1.83 GPa |

| Flexural Modulus | 19.0 msi / 131 GPa |

| Fiber Volume | 62% |

| Thermal Expansion Coefficient | -0.1 ppm/cm3 / -0.2 ppm/°C |

| Density | .054 lbs/in3 / 1.5 g/cm3 |

| Diameter Tolerance | +.005 / -.005″ |

| Glass Transition Temperature | 100° C |

| Matrix Material | Bisphenol Epoxy Vinyl Ester |